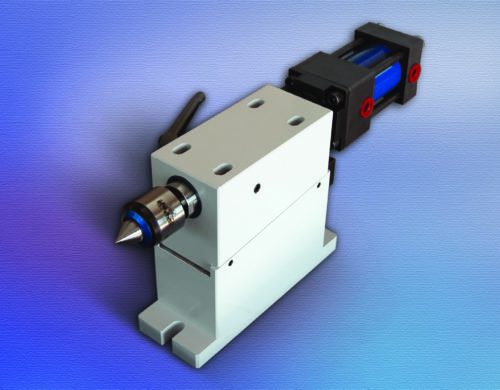

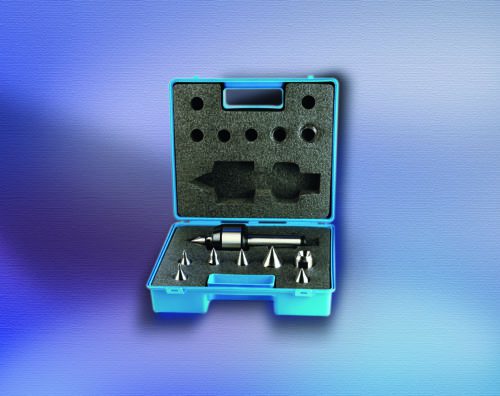

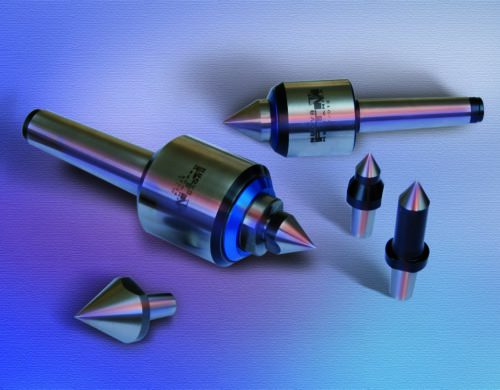

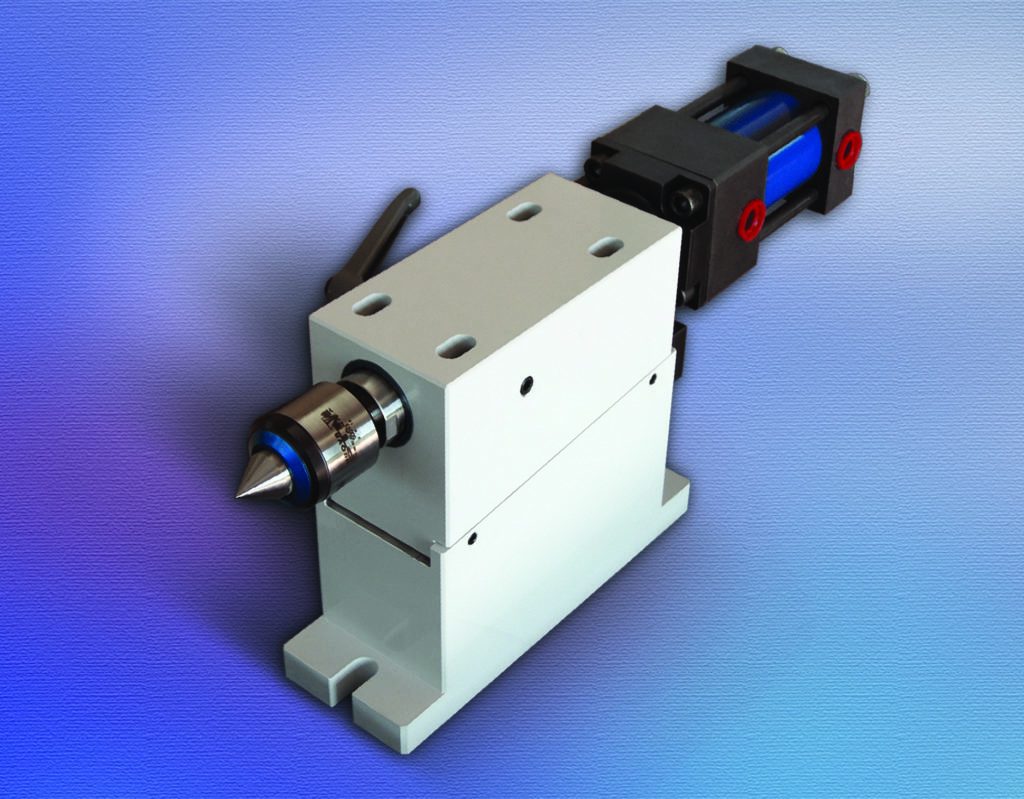

ITA, Inc. supplies PTM live centers, dead centers, and face drivers to ensure the best performance, highest accuracy and longest life while keeping costs low.

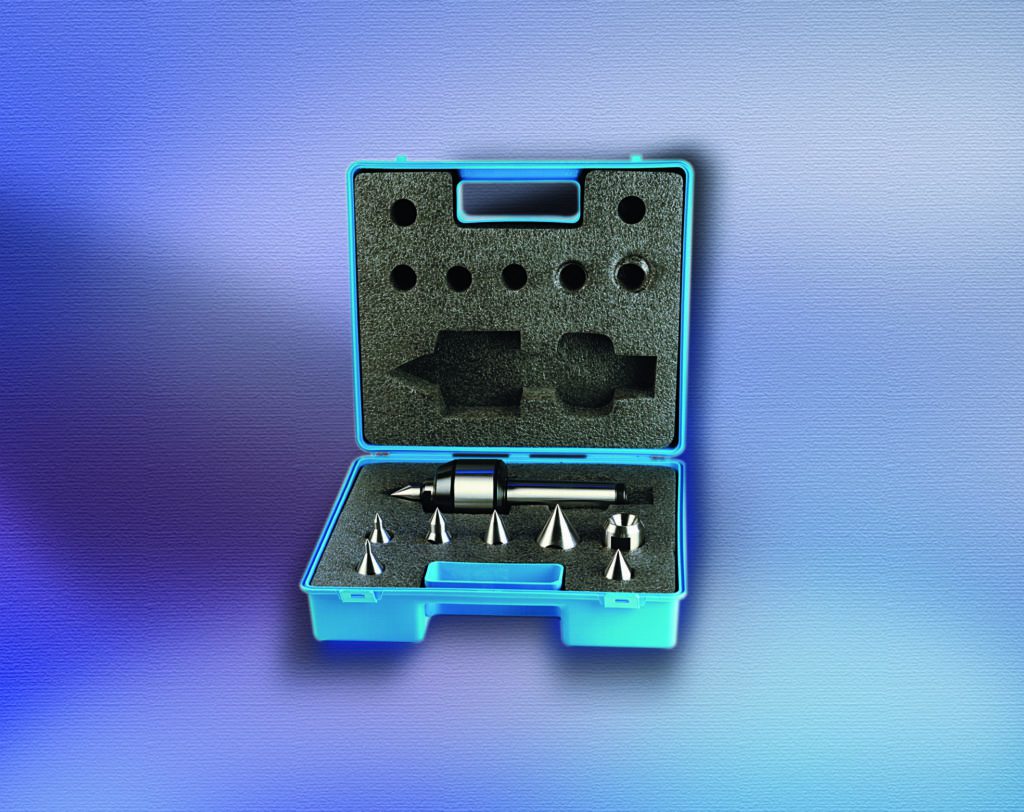

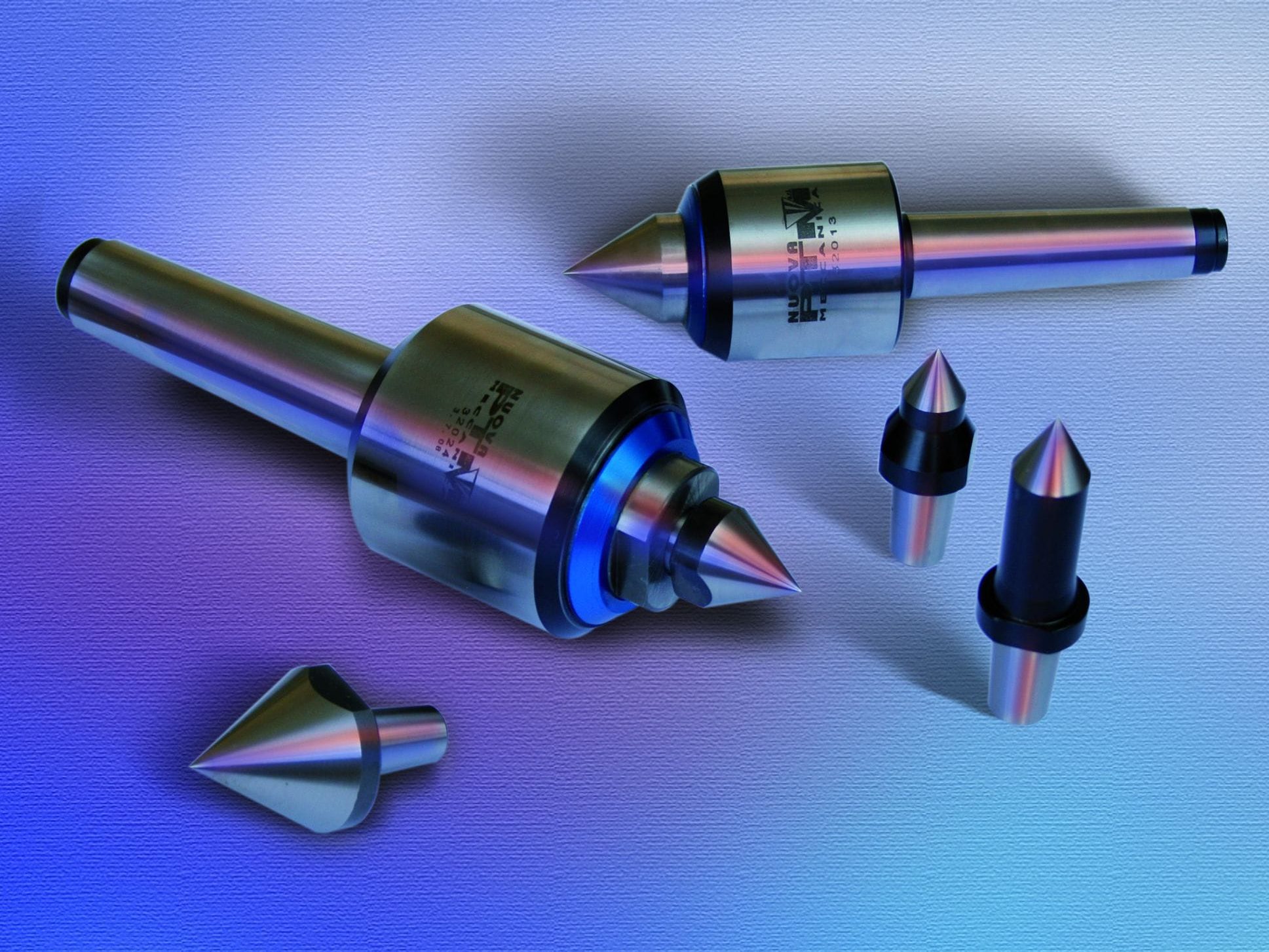

PTM is a leading manufacturer of standard and custom designed work holding products. They established their reputation and achieved success by offering a wide variety of products with emphasis on live centers, dead centers and face drivers for turning, grinding and gear cutting. PTM’s extensive line of products are expertly crafted and manufactured with the highest quality materials available.

Our Commitment To You

PTM’s extensive line of products are expertly crafted and manufactured with the highest quality materials available. In a word, PTM is fine craftsmanship at its best.

Best Performance

Engineered for maximum tool clearance while providing the highest rigidity to the workpiece.

Longest Life

All PTM products are manufactured to the highest standards and where required permanent lubricating grease and specially designed seals are used which guarantees to keep out fines and coolant including high pressure coolant.

Highest Accuracy

Utilizing high quality material and components, innovative design and manufacturing practices.

Ensure the best performance, highest accuracy, and longest life with standard and custom-designed PTM workholding products for turning, grinding, and gear cutting. For more information or help in choosing the right product for your machining process, call 410-777-8555 or contact us today.

*All specifications are subject to change without notice.