Machine shops lose thousands of dollars each year by manually cleaning out their coolant tanks. Without a coolant filtration system in place, tanks need to be cleaned several times a year and every cleaning takes hours. Our coolant filtration systems last for decades and typically pay for themselves in the first year!

ITA, Inc., in business for over 30 years, is the industry leader in these systems. Our team combines decades of knowledge and expertise with the highest level of premiere customer service.

Models

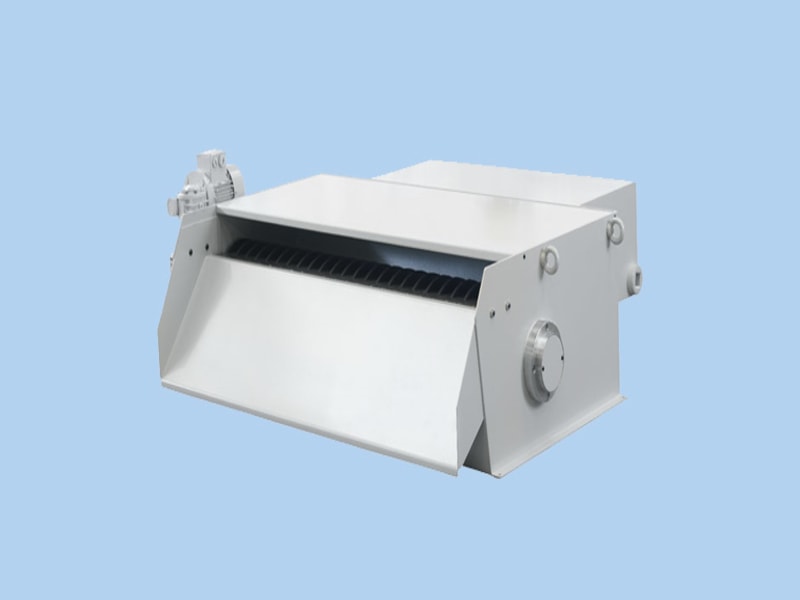

Model Roll

The CFS Model ROLL Coolant Filter, with automatic operation, is a specially designed filter and is suitable for water soluble, synthetic or straight oil coolant. The ROLL is made of heavy gauge steel and features an expanded filtering area. The revolving conveyor is made of heavy gauge non-metallic material (rigid for better support) and will not tear filter fabric. The chemically resistant, low-density float provides failsafe operation.

Model Disk

The CFS Model DISK is a magnetic separator that can be used alone or with our Model ROLL Coolant Filter (see our Model COMB below). The Model DISK is an economical and efficient method of filtering ferrous metal particles, fines and chips from water soluble, synthetic or straight oil coolant and provides many advantages, such as automatic continuous operation, self-cleaning and easy installation.

Model Comb

The Model COMB combines a gravity-fed coolant filter (our Model ROLL) with a magnetic separator (our Model DISK). This combination creates a two-stage filtration system, assuring a high degree of coolant filtration, as well as reducing filter fabric consumption. The Model COMB is manufactured with heavy gauge steel and epoxy coating offers high corrosion resistance to exposed parts. A translator control minimizes filter fabric usage and is advanced in incremental amounts automatically.

Operation

CFS coolant filtration systems use gravity to filter through a non-woven fabric filter media. When the fabric gets clogged, the float level control starts the conveyor to move clean filter fabric in position. The sludge collected on top of the filter fabric conveys to a removable sludge tank.

Benefits

- Made from heavy gauge steel construction.

- Tanks mounted on square section support rails to prevent corrosion and make movement easier.

- Moving parts made of durable materials, not plastic (drive shaft supported by sealed bearings, sprockets made of steel).

- Motors and electrical controls are non-overhanging to minimize the footprint and potential for damage.

- Filter media guarded to prevent damage to filter fabric roll.

- Filter media advances less per increment (lasts longer).

- Float level control is heavy-duty, protected and fail-safe.

- Made for water soluble and oil based coolants with a slick surface to resist sludge build-up.

- Not triggered by foam.

- Magnetic separator with interior baffle maximizes liquid contact time with magnetic disks.

- Safety cover on magnetic separator to prevent accidental contact with rotating parts and splashing of coolant.

- Magnetic separator discharges sludge onto the trailing edge of filter media to drain coolant/liquid from sludge before discharging into sludge tank.

- Sludge tank is easily removable.

Applications

CFS Filters are ideally suited to process coolants and wash fluids containing sludge of any type from:

- Grinders

- Lapping Machines

- Industrial Washing Machines

- Honing Machines

- Machining Centers

- Drawing Machines

- PIpe Forming Machines

- Much, much more!

Get Started!

Want to learn more about our CFS Coolant Filtration Systems? Contact us today and our highly trained customer service representatives will be happy to answer your questions.

ITA, Inc.

(410) 777-8555

info@itaquality.com

Request Coolant Filtration Systems Information

*All specifications are subject to change without notice.